Think Engineering Think EQuad

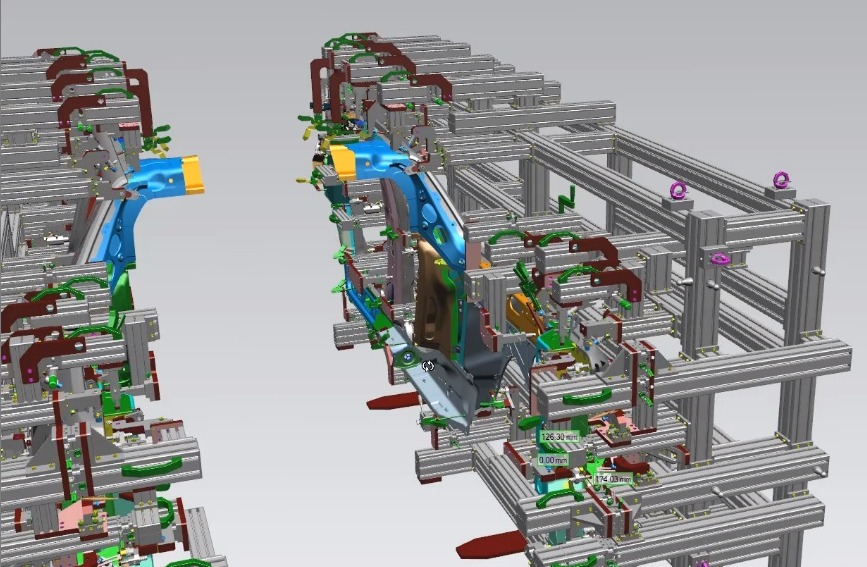

With our highly skilled Engineers, we provide the optimal solution for Engineering Design, Reverse Engineering, Concept Design, Industrial Design, Machine Design, Sheet Metal Design, Product Design, Piping Design, Harness (Wiring) Design, 2D Drafting, Computational Fluid Dynamics (CFD), Finite Element Analysis (FEA), Mold Flow Analysis (MFA), 3D Printing, Product Prototyping and Design Proofing. We offer Industrial Skill Training/ Internships / Placement Assistance with Government of India Certification in Chennai for Engineers

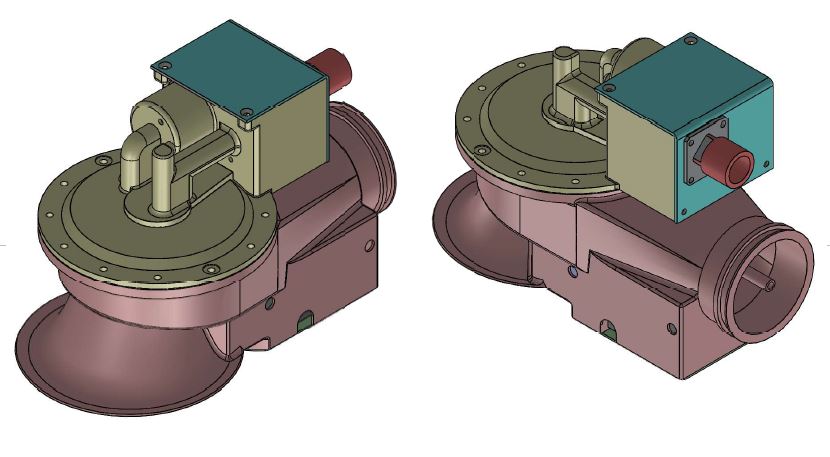

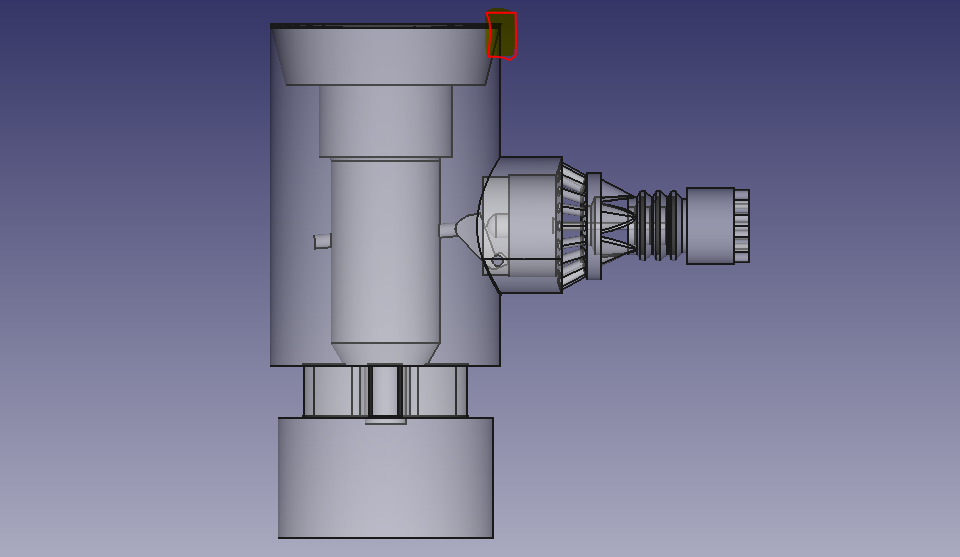

Mechanical Design Services

2D Drafting, 3D Drafting, 3D Modelling Services

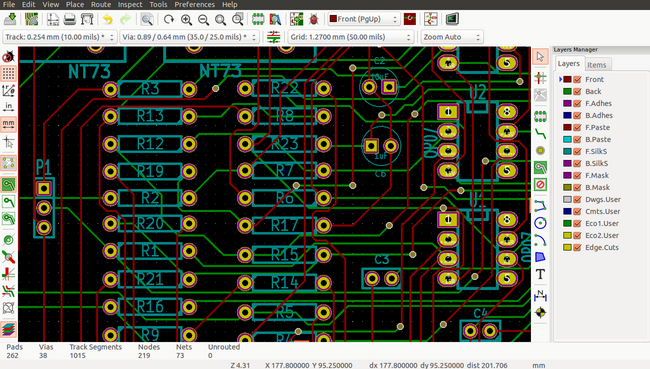

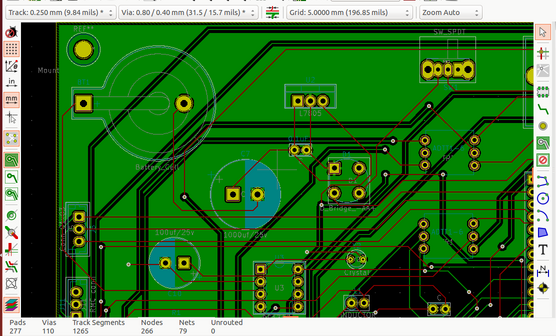

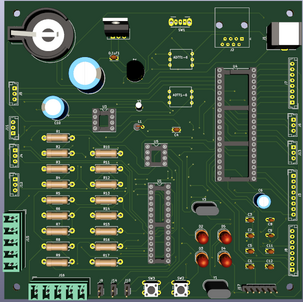

Industrial Design, Concept Designing Services (Electronic & Mechanical)

Piping Design, Harness Design, Product Design, Sheet Metal Design

Reverse Engineering

Product Development Services

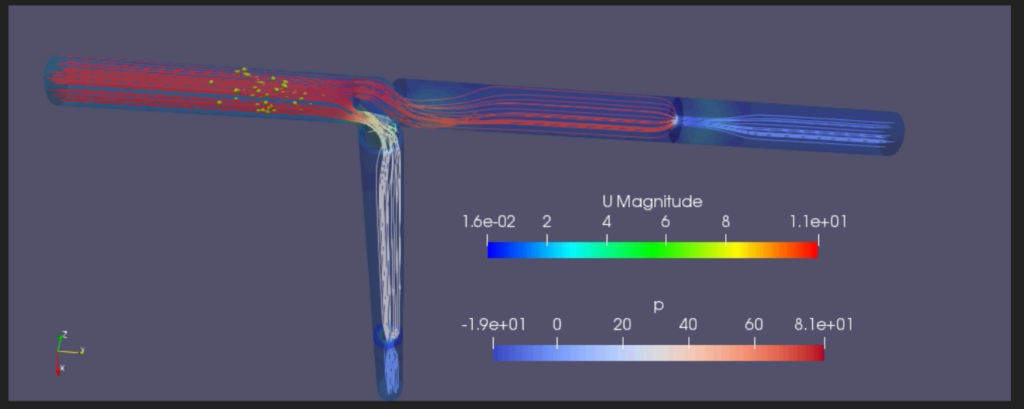

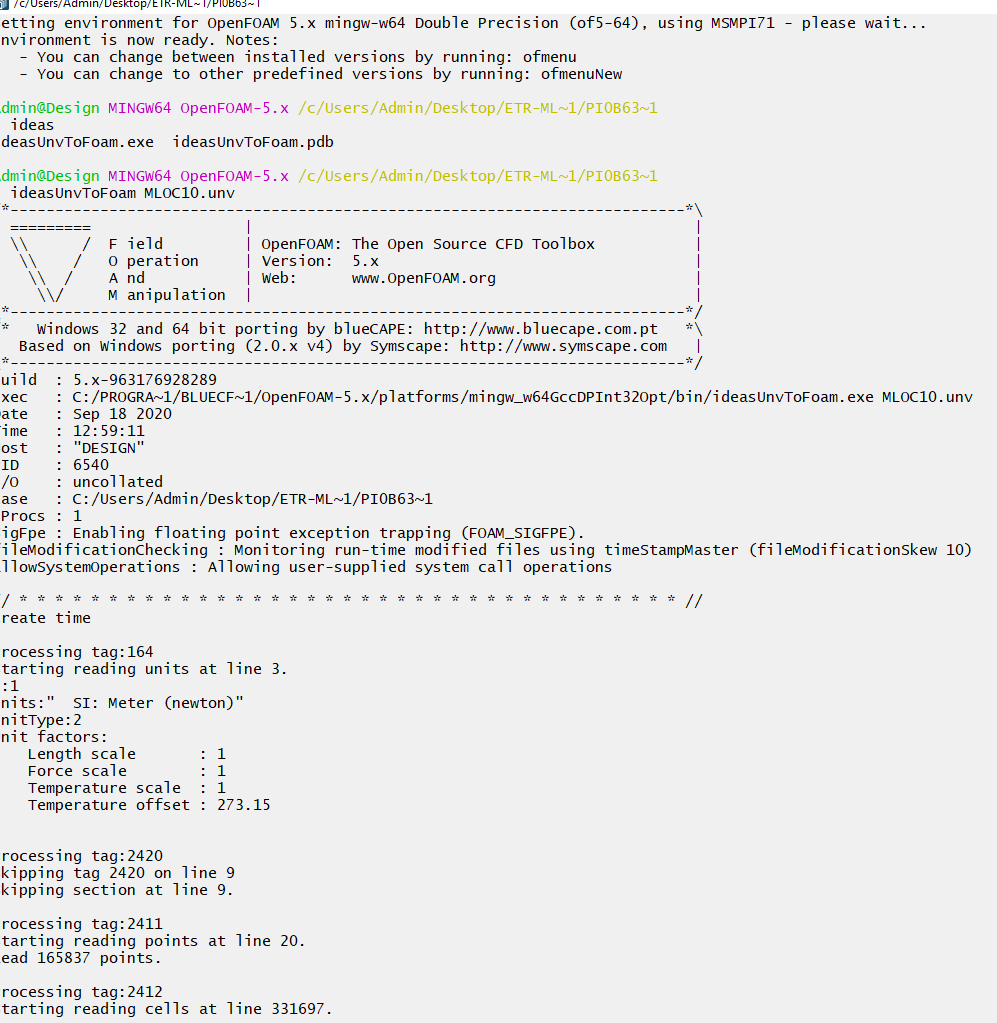

FEA, CFD, 3D Printing

In-plant Training in Chennai

Industrial Training in Chennai

Mechanical Internship in Chennai

Electronics Internship in Chennai

Robotics Internship in Chennai

We provide the best Engineering and Engineers as a service to the nation and to this society for the betterment of humanity and lifestyle

Our Mission

To provide affordable engineering solutions to industry and continually enhance availability of skilled engineers through Engineering Systems Thinking training

Our Vision

To be a market leader in providing affordable engineering services

DECEMBER INDUSTRIAL INTERNSHIP CALL FOR REGISTRATION

If you are looking for December Industrial Internship and Govt of India Certification for Core Departments ECE EEE EIE MECH AERO AUTO

Use the below link to register for the same with SECO EQuad Group of Industries in Chennai, India. https://docs.google.com/forms/d/13l1omdK0zPx1hIwFACdGh_qidlEUCXQLOPz0WH61fpk